|

Adhesion system

model (What is stickiness?)

Many people asked me about what kind of material the sticky pads

made out of and there is a large spectrum of surface energy. As I

learned more about molecular mechanics, however, it is

getting more convincing to me that adhesion is depends

more on geometry of structures than the type of material.

In the beginning of RiSE (Robots in Scansorial Environment)

project, winter of 2003, I was wondering about the mechanism

why sticky stuff stick on surfaces. What feature makes

things sticky? My hypothesis was that the more compliant the

structure of a system, the stickier it is. One approach

drawn from this concept is very simple

Adhesion system model that I made in Jan 2004.

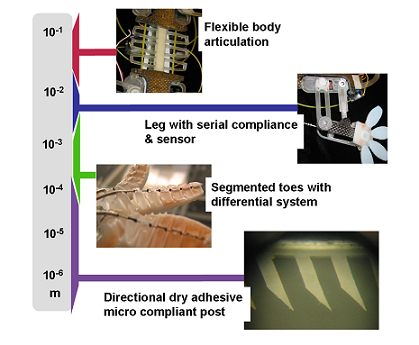

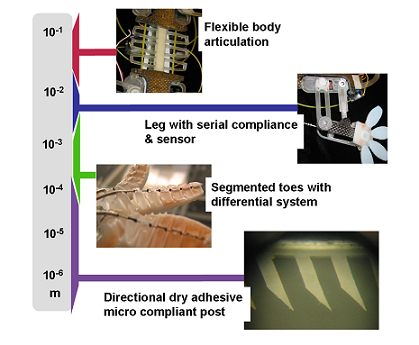

Hierarchical compliance system

As mentioned in adhesion model, surface conformation is essential in adhesion since

Van der Waals force is

very weak unless there is intimate contact between two

surfaces. Van der Waals force is known to be very weak,

although its usage is ubiquitous in our life. Most common

example is conventional tape that uses very soft material

for compliance.

Vertical climbing on various surfaces requires more

sophisticated system than single thin layer of soft polymer

used in tape. In natural and artificial

environment, roughness in many length scale is presented.

Thus, in order to maximize the number of molecules in

intimate contact between feet and wall surfaces,

corresponding length scale compliance is needed. Gekco species

also present hierarchical compliance in their body. Flexible

body and leg can conform at the centimeter scale. Toes

and soft skin are responsible for 1~2 millimeter scale.

Within a millimeter scale, specialized hair structures are

composed of lamellae, setae and nano scale spatulae covering

up to nanometer scale. Stickybot inherits similar

characteristic comprising 12 active actuator, 8 DOF serial

and 4 passive compliant DOFs in leg and 16 segmented toes

controlled via two stage differential cable driven system.

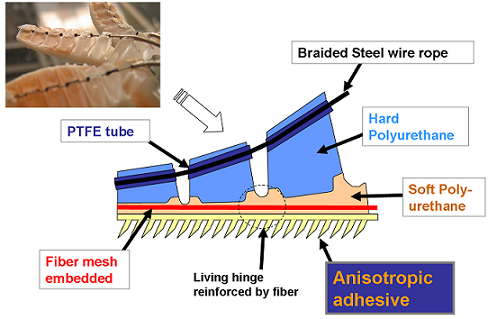

Directional

adhesion

The most

extraordinary feature of Stickybot is Directional adhesive.

Climbing robot are not

It has Anisotropic

structure featured controllable adhesion with

directionality in adhesion force. The

movie clip demonstrates directional adhesion

compared to conventional double sided tape. Unlike

conventional tape, it sticks on smooth surface with very

small preload and is also able to detach with by

reducing load. If it is loaded in desired

direction, it creates maximum contact minimizing stress

concentration along the contact area. if it is loaded in

wrong direction, the adhesion force is very low.

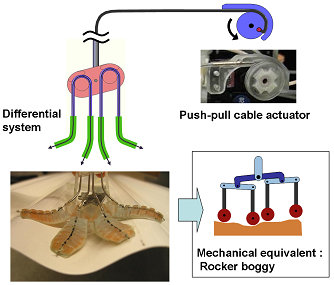

Underactuated system

An

underactuated system is a system that has more number

of degree of freedom than number of actuators. Additional

degree of freedom usually controlled by either spring damper

system or differential system. Although underactuated system

is introduced in order to reduce number of actuators, in

many cases, taking advantage of passive mechanical dynamics.

A good practical example is car suspension system.

Considering a car suspension system as a robot arm, you will

find 2 DOF

- Spring

damper system

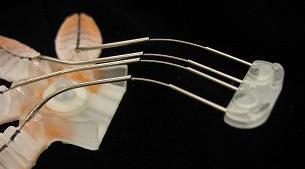

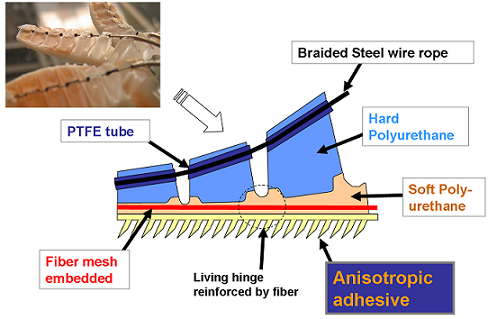

Foot design

What makes

Stickybot unique is its extraordinary design of foot. Its

foot has four segmented toes controlled by single push-pull

cable via two stage differential system. Three different

polymers are used and stiffened by fine fabric to minimize

shear stress concentration along adhesive pads. It took me

about three month to finalize design iterating more than

three times. Utilizing high surface energy of poly-urethane,

we can test various adhesive pads on Stickybot feet.

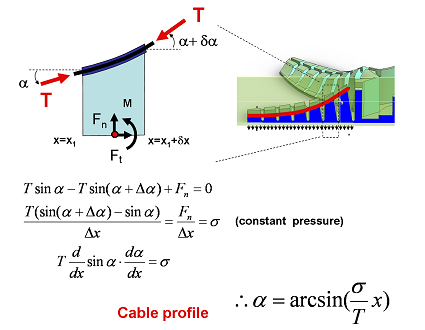

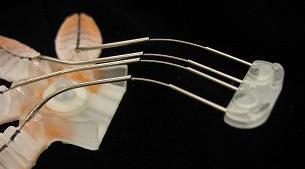

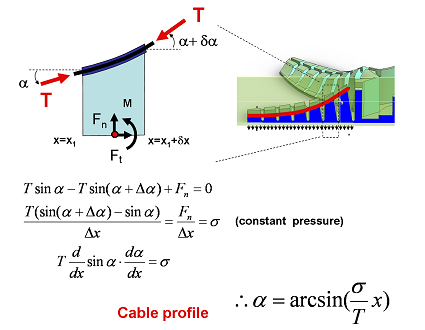

Its

interesting curvature of cable path is designed carefully in

order to ac hieve well distributed normal force on the

contact area. Since each toes has seven segments, it can

conform non flat surfaces. Despite its flexible structure,

reliable adhesion requires elaborated force

transmission system from cable tension to normal pressure on

contact surface. Its desired profile is calculated in such a

way shown on the diagram on right. hieve well distributed normal force on the

contact area. Since each toes has seven segments, it can

conform non flat surfaces. Despite its flexible structure,

reliable adhesion requires elaborated force

transmission system from cable tension to normal pressure on

contact surface. Its desired profile is calculated in such a

way shown on the diagram on right.

Basic idea is

to create uniform normal pressure that caused by cable angle

differentiation. Each segment should have same amount of

force assuming constant cable compression force.

Differential cable system is employed in order of minimizing number of actuators and force balance among four

toes. One equivalent mechanical system is double rocker bogie system.Upper stage differential

actuation is rocker and one cable connecting two toes

enables lower stage differential system.

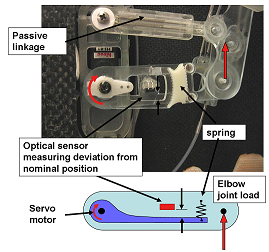

Leg design

with force sensor

|

hieve well distributed normal force on the

contact area. Since each toes has seven segments, it can

conform non flat surfaces. Despite its flexible structure,

reliable adhesion requires elaborated force

transmission system from cable tension to normal pressure on

contact surface. Its desired profile is calculated in such a

way shown on the diagram on right.

hieve well distributed normal force on the

contact area. Since each toes has seven segments, it can

conform non flat surfaces. Despite its flexible structure,

reliable adhesion requires elaborated force

transmission system from cable tension to normal pressure on

contact surface. Its desired profile is calculated in such a

way shown on the diagram on right.